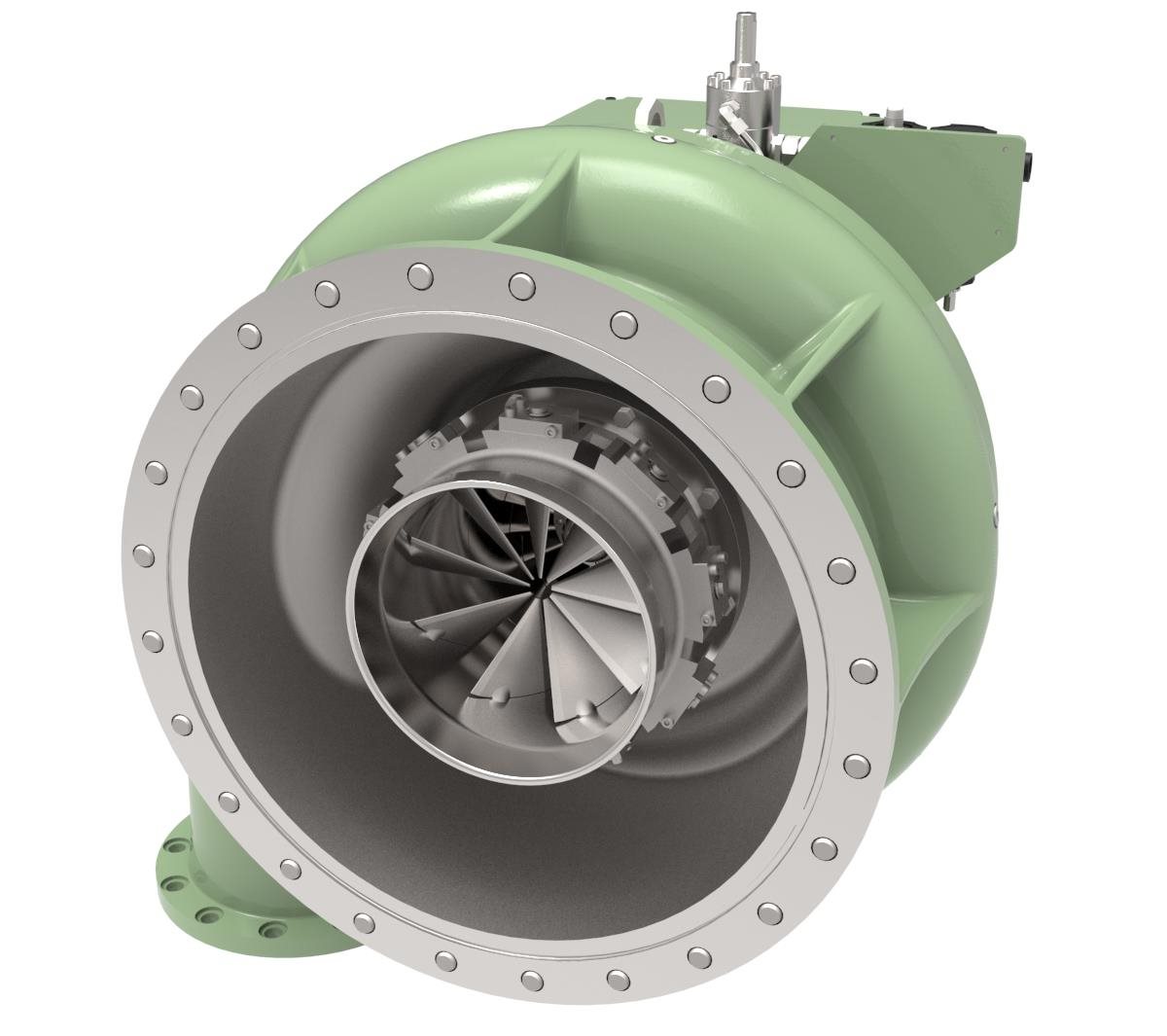

Centrifugal Blowers

Our range of turbo blowers encompasses industrial type blowers used in the power, mining and water industries. We also have turbo compressors that are suited for API specification type applications in the downstream oil and gas industry.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team